Precision Parts Examples

Large-Long Bar Work

12in. diameter by 19in. long between spindles with live tooling. Longer work if your part can be passed through a 1-5/8" capacity sub-spindle draw tube. Keyways, flats, threading and cross drilling/tapping on and off center.

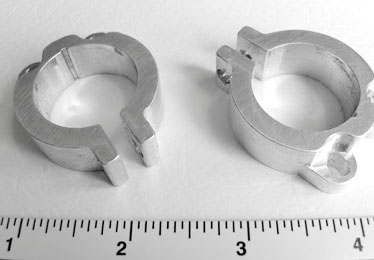

5-Axis Turn-Mill

Five axis capability allows us to produce parts in one operation complete with milled flats, keyways, turned threads, cross drilled and tapped threads on or off center line of part as well as back facing and live tool work on both ends of a part.

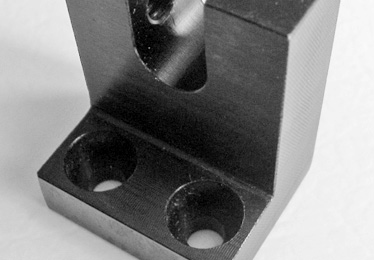

CNC Vertical Milling

We offer vertical milling with indexing and pallet changing machines are available to help produce parts as complete as possible. We machine carbon and alloy steels, stainless steels, aluminum, copper, brass and bronze.

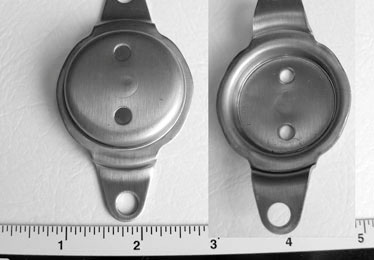

Precision Turning

Using traditional 2-Axis and sophisticated multi-axis "turn-mill" - we can turn small parts too, to exacting tolerances (typically .002 to .005 TIR), in a variety of materials, from tool-steel to copper, brass and aerospace alloys.