Precision Machining for Northern California

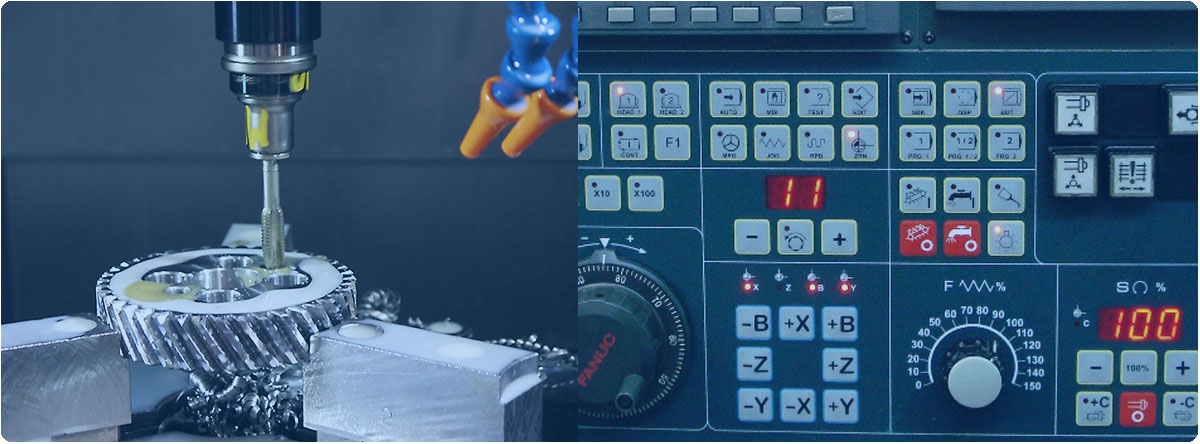

Milling, Turning, 5-Axis Turn-Mill & Stamping

Since the 1950's, Morgan Manufacturing has been a trusted supplier of precision machined parts to ... industrial, energy, transport, consumer and equipment OEM customers throughout Northern California.

We do … bar work up to 12in. dia. and 19in. long (longer work if it is 1-5/8in. dia. through a sub-spindle), 5-axis Mill-Turn ("one-and-done") with back-facing, and live tooling on both ends of the work-piece… and we do Stamping (with our 250T Cincinnati Open Back Press).

Today our typical customer wants aluminum, steel, tool steels and alloys machined to exacting tolerance (.002 to .005 in.), in small to several 1,000's lot sizes, 'just-in-time.' We meet this need through a rapid, accurate quote available to you online and whether your part is turned, milled or stamped - our attention to your unique needs is the ultimate.

Parts, Kitting & Added-Value Services Support Your Product Life-Cycle

We realize our customers must thrive in a globally competitive marketplace - so we respond to your need for cost-competitive, uncompromising quality and on-time delivery throughout Northern California. With an array of production techniques available, from precision 4-axis milling and turning to stamping - we can offer 'one-shop' capability for new part designs, 'kitting' and higher-volume end-of-life parts that may no longer be cost-effective for in-house production.

End-to-End Production Support

Whether you're starting with a rough-drawing for a new design or you're looking for end-of-life alternative production from a trusted partner, Morgan Manufacturing offers design-assistance, alternate sourcing and the ability to simplify all of your production requirements, including heat-treating, anodizing, welding, light-assembly, painting and drop-shipping to your assembly or distribution locations.